Polymer polyols are a specialized class of polyether polyols synthesized by incorporating solid polymer particles—such as polystyrene, polymethyl methacrylate, or acrylonitrile-butadiene-styrene—into a polyether polyol matrix. This is typically achieved through in situ polymerization of monomers within the polyol phase, resulting in a stable dispersion of solid polymer domains within the liquid polyether polyol.

- Base Polyol: Polyether polyol (e.g., poly(propylene glycol), poly(ethylene glycol))

- Polymer Phase: Solid polymer particles (e.g., polystyrene, polymethyl methacrylate)

- Appearance: Milky white to light yellow viscous liquid

- Functionality: Typically 2–3 hydroxyl groups per molecule

- Molecular Weight: Varies based on the base polyol and polymer phase

Key Applications

Polymer polyols are primarily utilized in the production of high-load-bearing or high-modulus flexible and semi-rigid polyurethane foam products. Their applications include:

- Flexible Polyurethane Foams: Used in the manufacture of cushioning materials for furniture, mattresses, automotive seating, and packaging.

- Semi-Rigid Polyurethane Foams: Employed in applications requiring a balance between flexibility and rigidity, such as in insulation panels and structural components.

- Molded and Block-Formed Foams: Integral in the production of molded foam parts for automotive interiors, appliance components, and construction materials.

Advantages

- Enhanced Mechanical Properties: The solid polymer phase imparts increased hardness, tensile strength, and tear resistance to the resulting foam products.

- Reduced Raw Material Consumption: By partially replacing general-purpose polyether polyols, polymer polyols enable the production of low-density foams with high load-bearing properties, optimizing material usage.

- Improved Processability: The stable dispersion of solid polymer particles facilitates consistent foam formation and molding processes.

- Customization: The ratio of polymer phase to polyether polyol can be adjusted to meet specific performance requirements, offering flexibility in foam formulation.

Safety and Handling

- Storage: Store in tightly sealed containers, away from heat and sources of ignition, in a cool, dry place.

- Handling: Use appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing, when handling polymer polyols.

- Disposal: Dispose of in accordance with local environmental regulations.

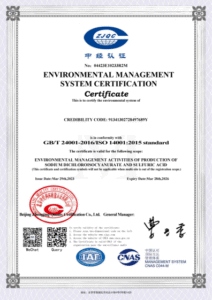

Certificates

Payment terms: Various payment methods are available, including T/T IN ADVANCE, Part repayment and part credit, etc.