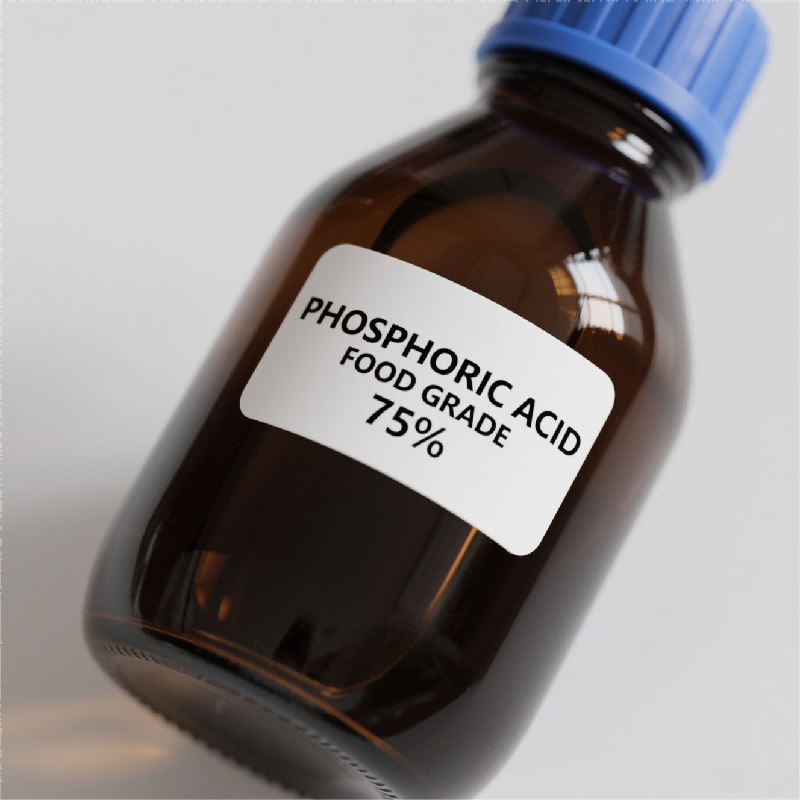

Product Overview

Our PHOSPHORIC ACID FOOD GRADE 75% is an orthophosphoric acid solution developed for the food and beverage industry. This high‑purity, liquid acidulant functions as a flavour enhancer, yeast nutrient and acidity regulator. It is suitable for use in a wide range of edible formulations—beverages, jams, confectionery, dairy and more. As observed in similar food‑grade offerings, the product is “a colourless, odourless, non‑volatile liquid” grade specifically designated for safe use in food applications.

Key Features & Benefits

Flavor profile and acidulation: As an acidulant, it delivers a clean tangy/sour taste which is especially useful in soft‑drinks, jams, jellies and other sweet‑acid foods. For example, food‑grade phosphoric acid is used to acidify beverages such as colas and jams.

Acidity regulation & stability: Supports pH control in formulations to help maintain flavour consistency, inhibit microbial growth, and extend shelf life in acidic food systems.

Yeast nutrient & phosphate source: In certain fermented or yeast‑based applications, phosphate compounds serve as nutrients; this acid can play a role when properly formulated.

Versatile across food & beverage applications: Suitable for carbonated soft drinks (especially cola‑type), jams/preserves, dairy products (cheese, processed cheese), fats and shortenings, dressings and sauces.

Compliance and certification‑friendly: Available in versions certified for drinking water or food‑industry use (e.g., NSF/ANSI‑60 listing) which underscores its suitability for high‑purity applications.

Typical Applications

Carbonated soft drinks (colas): To impart that characteristic sour/tang flavour and to help balance high sweetness levels.

Fruit jams, jellies & preserves: To acidify the formulation, enhance flavour and regulate pH for safety and texture.

Dairy & processed cheese: Used to control acidity in cheese manufacture, processed cheese emulsions or as a functional acidulant in dairy systems.

Fats, shortenings & baking ingredients: Employed in the food industry for pH control in fats/shortenings, and other processed food components.

Sauces, dressings, emulsions: Functions as an acidulant and stabiliser in pH‑sensitive sauces, dressings and emulsified systems.

Fermented / yeast‑based foods: When phosphate balance or yeast nutrition is a part of the process, phosphoric acid derivatives may contribute.

Regulatory & Safety Considerations

As a food‑grade acid, usage must comply with prevailing food‑additive regulations and good manufacturing practice (GMP). The product should be used in line with dosage guidance, formulation compatibility and labelling requirements.

Although food‑grade, this is still a strong acid—appropriate handling and dilution practices are required (add acid to water, not water to acid; wear protective equipment, acid‑resistant equipment) to ensure safety in processing.

Ensure packaging integrity, traceability and verification of grade (food vs technical) to avoid cross‑contamination of unintended grade.

Certification such as NSF/ANSI‑60 (for drinking‑water chemicals) offers additional assurance of purity and control.

Packaging & Supply Options

Available in industrial‑scale packaging suited to food & beverage operations: e.g., drums, totes, bulk tanker loads. For example, one supplier lists 15 gal drums, 55 gal drums and 3400 lb totes for their 75 % food grade offering.

Logistics options can be adapted for food‑industry supply chains, hygiene standards and storage compatibility.

Handling & Storage Recommendations

Store in a cool, dry, well‑ventilated area. Keep container tightly closed when not in use.

Avoid contact with incompatible materials such as strong bases, alkalis or reactive metals.

Use acid‑resistant containers and transfer equipment.

During dilution, always add acid to water (never water to acid) to prevent exothermic hazards.

Ensure good housekeeping to prevent spills or contamination of adjacent materials — especially important in food manufacturing settings.

Provide documentation for food‑grade handling, traceability, and cleaning protocols in the manufacturing site.

Certificates

Payment terms: Various payment methods are available, including T/T IN ADVANCE, Part repayment and part credit, etc.